- About

- Admissions

- Academics

- Athletics

- Student Life

« Back

Balsa Wood Bridges, May They Rest in Pieces

April 17th, 2017

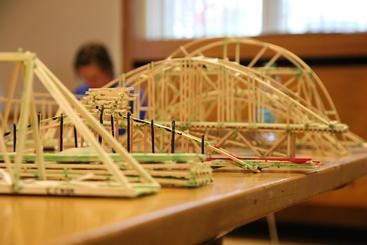

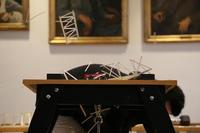

The results are in for the Fourth Form’s Balsa Bridge Competition. This annual event challenges each student in the Form’s Pre-Engineering class to design and construct a bridge using slender balsa wood strips and glue. Each bridge must span 18 inches and must be wide enough to allow the test vehicle to “park” in the center of the bridge. Weights are gradually added to projecting bars connected to the vehicle until bridge failure occurs. All the bridges were weighed before the competition and each bridge’s weight, and total load before failure were used to develop an efficiency ratio. Last year’s winner topped out at 45 pounds.

The results are in for the Fourth Form’s Balsa Bridge Competition. This annual event challenges each student in the Form’s Pre-Engineering class to design and construct a bridge using slender balsa wood strips and glue. Each bridge must span 18 inches and must be wide enough to allow the test vehicle to “park” in the center of the bridge. Weights are gradually added to projecting bars connected to the vehicle until bridge failure occurs. All the bridges were weighed before the competition and each bridge’s weight, and total load before failure were used to develop an efficiency ratio. Last year’s winner topped out at 45 pounds.

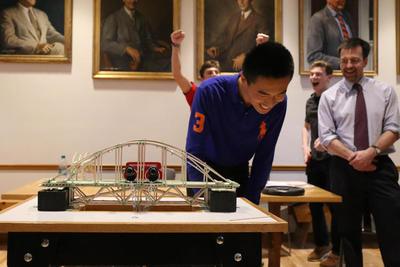

Zhenghao Dong with his winning bridge

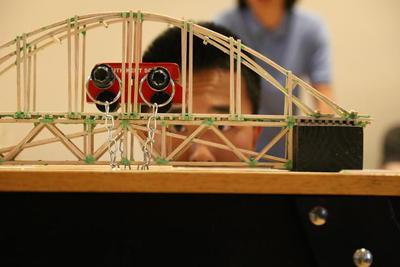

This year’s winning bridge, with an Efficiency Ratio of 1.20 and supporting an impressive 89 lbs., was engineered by Zhenghao Dong (Qingdao, China). Zhenghao used a very rigid substructure and carefully crafted arches to direct the stresses of the load toward the ends of his bridge. Patrick Harrington’s (Huntington Beach, CA) bridge was a close second with an ER of 1.58 and a supported load of 44 pounds. Rong Huang’s (Beijing, China) bridge came in third with a 1.67 ER and a 34-pound load, Hayden Giampietro (South Kent, CT) was fourth with a 1.73 ER and 44 pounds, and Jack Robilotti (New York, NY) earned fifth place with a 1.85 ER and 59 pounds.

The four runners-up

Zhenghao credited his elaborate substructure for providing his winning bridge with the strength to redirect the considerable forces away from the center of the bridge, adding “I also made sure every joint of my bridge was strong, so there would be no obvious point of weakness.” Vertical supports from the roadbed to arches also strengthened the road surface under the test vehicle.

The winning bridge design

Mr. Berghold, the Pre-Engineering teacher, was pleased with boys’ results. “While project grades were not strictly based on the Efficiency Ratio,” he noted, “some of the strongest bridges were also the ones which incorporated more complex elements like bent and laminated arches over carefully-constructed substructures. I wanted to reward those who took some risks; in many cases, those risks paid off.”

Next year’s engineers have a very high bar to overcome!